Introduction

Think about how your smartphone runs—every function depends on the tiny circuits inside. Now imagine the complexity of robots and industrial machines. Their intelligence, efficiency, and reliability all depend on advanced Printed Circuit Boards (PCBs). Enter Global Well PCBA, a leading Chinese PCB and PCBA manufacturer delivering solutions that power robotics and industrial automation worldwide.

In this article, we’ll explore how Global Well PCBA helps industries build smarter robots and automated systems, their cutting-edge technologies, and why they’re a trusted partner for innovation.

What is Global Well PCBA?

Global Well PCBA is a professional PCB and PCBA manufacturing company based in China. Their website, available in English, makes it easy for global clients to access their services.

They specialize in:

- PCB fabrication – single-layer, multilayer, rigid, flexible, and rigid-flex PCBs

- PCB assembly (PCBA) – SMT, THT, and mixed assembly services

- Component sourcing and turnkey solutions – providing everything from prototype to mass production

With years of expertise, they’ve become a reliable supplier for industries like telecommunications, medical devices, automotive, robotics, and industrial automation.

The Importance of PCBs in Robotics

Robotics wouldn’t exist without PCBs. Why? PCBs are the nervous system of robots, connecting processors, sensors, actuators, and communication modules.

For example:

- Robotic arms need PCBs to process signals from motion sensors.

- AI-powered robots use high-density PCBs to handle real-time decision-making.

- Autonomous robots rely on high-frequency PCBs for communication and navigation.

Put, robots are only as good as the PCBs inside them.

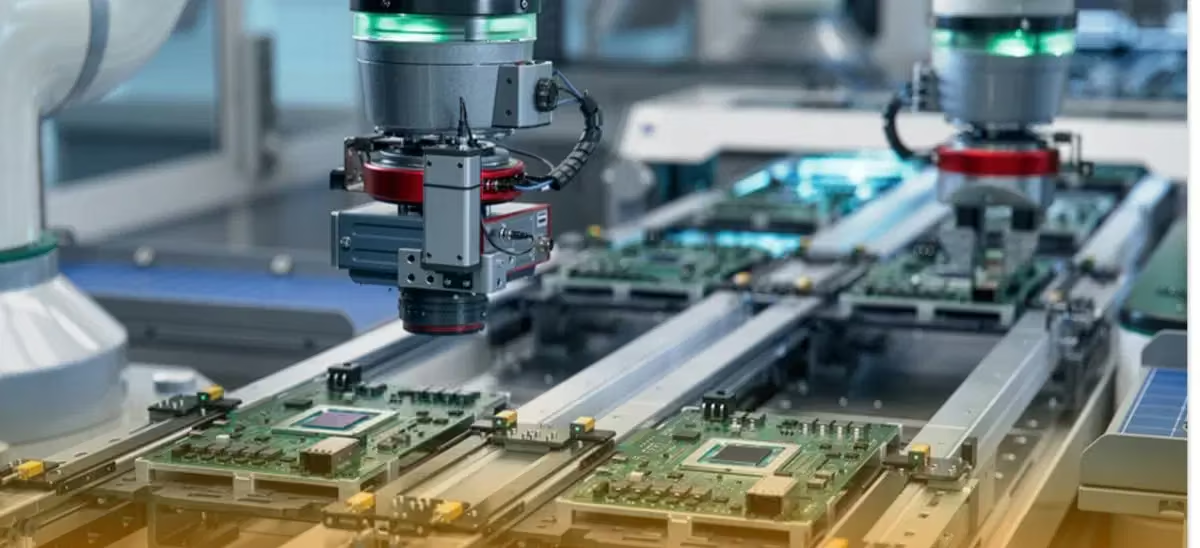

Industrial Automation and PCB Assembly

Industrial automation is reshaping factories with smart machines, sensors, and control systems. PCBs are the core enablers of these innovations.

In automation:

- PCBs power PLCs (Programmable Logic Controllers) that control machinery.

- IoT-enabled boards collect and share data in real time.

- Rigid-flex boards allow compact, durable solutions for complex machinery.

Global Well PCBA’s assemblies bring stability, scalability, and reliability to smart factories worldwide.

Global Well PCBA’s Advanced Manufacturing Capabilities

Global Well PCBA stands out for its technical expertise, offering advanced solutions such as:

- Rigid, Flexible, and Rigid-Flex PCBs: ideal for robotics with moving parts.

- High-Frequency PCBs: essential for telecommunications and fast data transfer.

- HDI PCBs: compact, multilayer boards that power AI and miniaturized devices.

Their cutting-edge production ensures precision, durability, and performance—key factors in robotics and automation.

Why Robotics Depends on High-Quality PCBAs

In robotics, a single malfunctioning circuit board can halt an entire production line. High-quality PCBAs are critical for:

- Maintaining precision and accuracy in robotic tasks

- Ensuring long-term durability in harsh industrial environments

- Reducing downtime and repair costs

That’s why industries turn to reliable manufacturers like Global Well PCBA.

Applications of Global Well PCBA in Robotics

Robotics applications powered by Global Well PCBA include:

- Collaborative robots (Cobots): Safe, human-friendly robots for factories.

- Autonomous Guided Vehicles (AGVs): PCBAs manage navigation and communication.

- Robotic welding and assembly machines: PCBAs control precision tools in automotive manufacturing.

These applications prove the critical role of PCBAs in advancing robotics.

Applications in Industrial Automation

Global Well PCBA also plays a huge role in industrial automation systems, powering:

- Process control systems that manage entire production lines.

- Programmable Logic Controllers (PLCs) are used in factories worldwide.

- IoT-enabled smart machinery that improves decision-making and efficiency.

Quality Assurance and Testing at Global Well PCBA

To ensure world-class performance, Global Well PCBA invests heavily in quality assurance. Their process includes:

- AOI (Automated Optical Inspection)

- X-ray testing for solder joint accuracy

- Functional testing for real-world reliability

They comply with international standards such as IPC, ISO, and RoHS, making their boards safe and reliable for global industries.

Customization for Industry Needs

One-size-fits-all doesn’t work in robotics and automation. Global Well PCBA offers customized PCB solutions:

- Prototype development for startups

- Low-volume production for R&D labs

- High-volume manufacturing for large-scale industries

This flexibility makes them a preferred partner for innovation-driven companies.

Case Studies: Global Well PCBA in Action

- Manufacturing Robotics: Global Well PCBA supplied rigid-flex PCBs for robotic arms, improving efficiency and reducing space.

- Telecommunications Automation: High-frequency PCBs enabled reliable, high-speed communication systems in automated networks.

These examples highlight how Global Well PCBA’s expertise is shaping industries.

Benefits of Partnering with Global Well PCBA

- Cost-effective PCB manufacturing in China

- Strong international logistics network

- Expertise in complex, high-tech PCB solutions

- English-language support for global clients

Challenges in Robotics & Automation PCBs

The PCB industry faces challenges such as:

- Miniaturization – demand for smaller, more powerful boards

- Heat management – preventing circuits from overheating

- Signal integrity – especially in high-frequency applications

How Global Well PCBA Solves These Challenges

Global Well PCBA addresses these issues by:

- Using advanced laminates and substrates for stability

- Employing thermal vias and copper pours for heat management

- Designing boards with signal integrity in mind for high-frequency systems

The Future of Robotics and Automation with PCBs

The future looks bright, with trends like:

- AI integration in robotics

- 5G-enabled industrial automation

- IoT-powered PCB solutions

Global Well PCBA is at the forefront, preparing solutions for tomorrow’s challenges.

Why Choose Global Well PCBA?

If you’re looking for a partner that combines technical expertise, affordability, and reliability, Global Well PCBA is a top choice. Their solutions empower industries to innovate, grow, and automate with confidence.

Conclusion

Robotics and industrial automation depend on reliable, advanced PCB solutions, and Global Well PCBA delivers just that. With their expertise in rigid-flex, high-frequency, and customized PCBAs, they play a pivotal role in driving automation across industries worldwide.

FAQs

1. What industries does Global Well PCBA serve?

They provide PCBs and PCBAs for robotics, telecommunications, automotive, medical devices, and industrial automation.

2. Why are rigid-flex PCBs important in robotics?

Rigid-flex PCBs save space and improve durability, making them perfect for robotic arms and moving components.

3. Does Global Well PCBA handle component sourcing?

Yes, they offer turnkey PCB assembly services, including sourcing of electronic components.

4. How does Global Well PCBA ensure product quality?

They use AOI, X-ray inspections, and comply with IPC and ISO standards to ensure high-quality boards.

5. Can Global Well PCBA support small businesses or startups?

Absolutely. They provide prototype and low-volume production services tailored for startups and R&D projects.